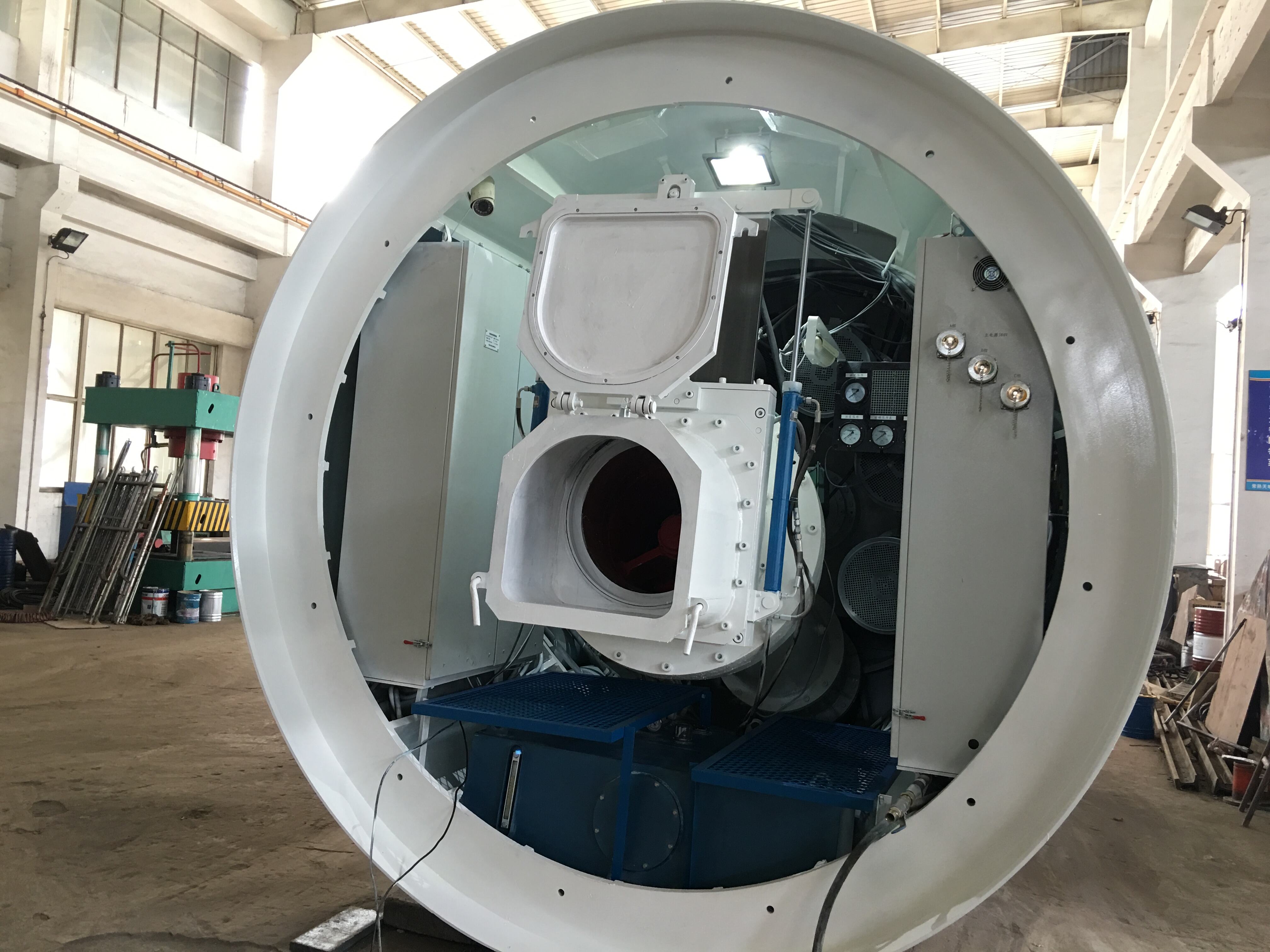

micro tunnel boring machine supplier

At the forefront of underground construction technology, our micro tunnel boring machine supplier offers innovative solutions designed for a variety of subterranean projects. These machines are engineered with precision to perform main functions such as drilling, cutting, and advancing tunnels with minimal disruption to the surface. Technological features include advanced navigation systems, remote control operations, and modular designs that allow for flexibility in various soil conditions. Whether it's for utility installations, water conveyance, or subway expansion, these micro tunnel boring machines are integral to urban development and infrastructure growth.