quality tbm tunnel boring machine

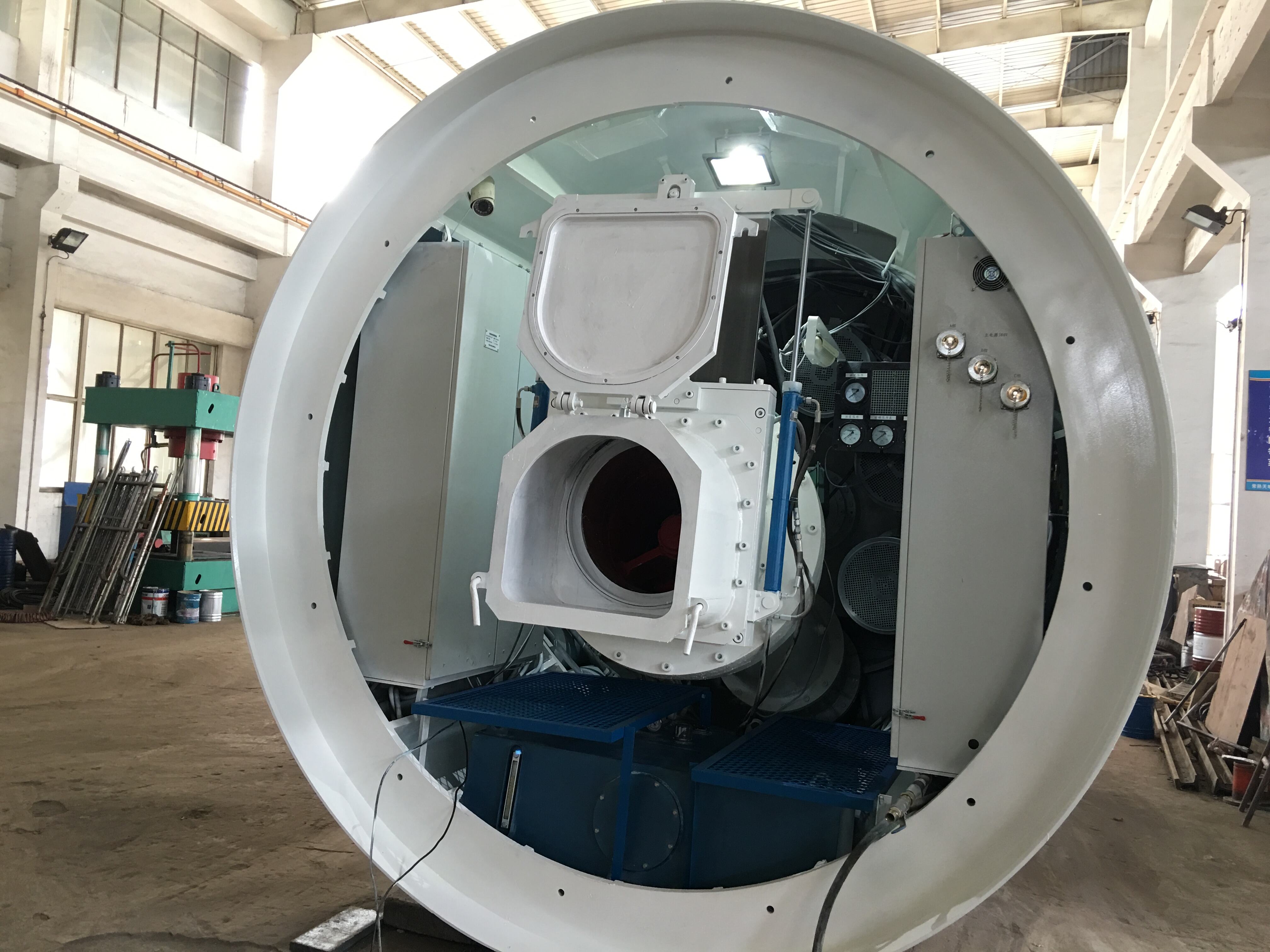

The quality TBM (Tunnel Boring Machine) represents the pinnacle of tunneling technology, designed for efficiency and reliability in underground excavation. This machine's main functions include drilling, cutting, and removing soil or rock as it progresses, creating a tunnel with a pre-determined diameter and alignment. Technological features such as a robust cutterhead, advanced hydraulics, and precision guidance systems ensure optimal performance. Applications of the TBM are widespread, from constructing subway tunnels and water conveyance systems to creating passages through mountains for highways and railways. Its modular design and automated features make it adaptable to a variety of geological conditions and project requirements.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY