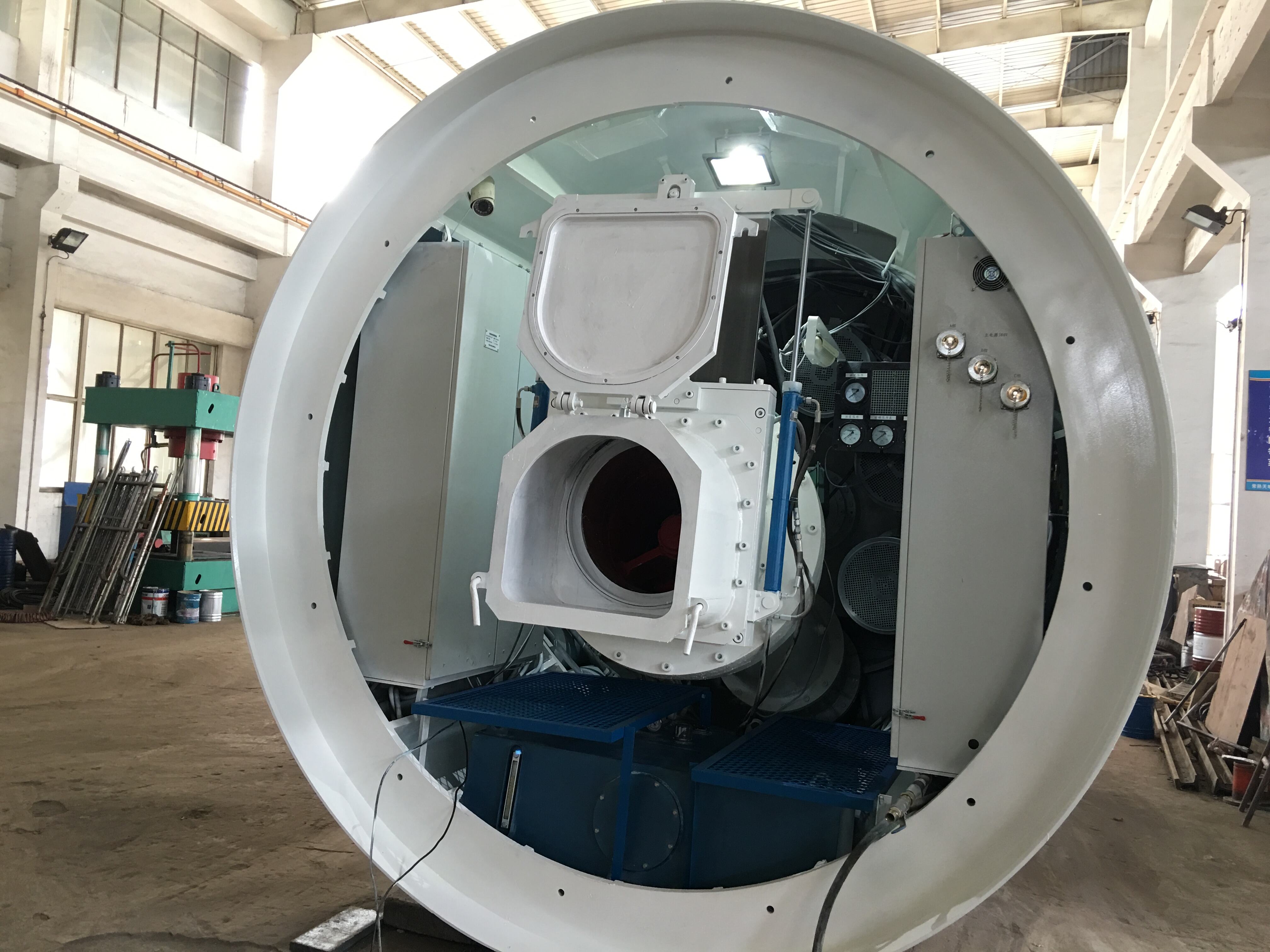

quality tunnel drilling equipment

Our quality tunnel drilling equipment represents the pinnacle of engineering designed for the excavation of tunnels. The main functions of this equipment include rock drilling, boring, and breaking, facilitated by its advanced technological features such as a robust construction, automated drilling systems, and precision control mechanisms. The equipment is versatile and can be used in a range of applications including mining, construction of subways, and water tunnels, ensuring efficient and safe excavation processes. With high durability and performance, this equipment stands out as a vital component in any tunneling project.