A micro pipe jacking machine helps you install utility tunnels and conduits underground without digging trenches. It combines excavation and pipe installation into one precise and efficient process. This tool minimizes surface disruption and works well in tough soil conditions, making it an ideal choice for modern construction projects.

Overview of Micro Pipe Jacking Machines

What is a Micro Pipe Jacking Machine?

A micro pipe jacking machine is a specialized tool designed for underground construction. It allows you to install pipes and tunnels without digging large trenches. This machine uses hydraulic jacks to push pipes through the soil while simultaneously removing the excavated material. It works in confined spaces, making it ideal for urban areas or locations with limited access. You can rely on it to handle various soil types, including clay, sand, and even rocky conditions.

Key Components and Features

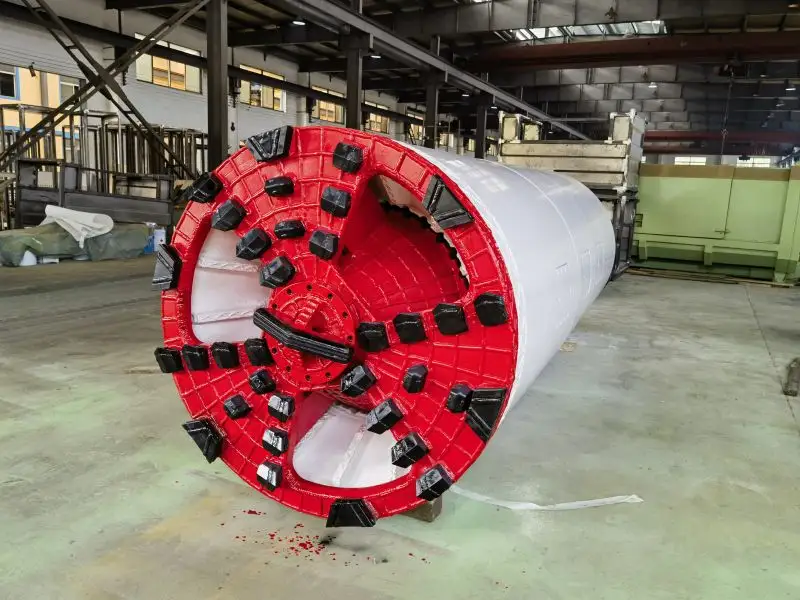

The micro pipe jacking machine consists of several essential parts. The cutting head at the front breaks through the soil. Behind it, the jacking frame provides the force needed to push the pipes forward. A guidance system ensures the machine stays on the correct path. Additionally, a slurry or spoil removal system clears the excavated material efficiently. These components work together to deliver precise and controlled tunneling. Some machines also include advanced features like laser guidance for improved accuracy.

How It Differs from Traditional Methods

Unlike traditional open-cut methods, a micro pipe jacking machine minimizes surface disruption. You don’t need to dig up roads or landscapes, which reduces environmental impact and saves time. Traditional methods often require more labor and equipment, while this machine streamlines the process. It also offers greater precision, ensuring the pipes are installed exactly where they need to be. This makes it a more efficient and cost-effective solution for modern infrastructure projects.

Step-by-Step Process of Operation

Site Preparation and Setup

Before you begin using a micro pipe jacking machine, you need to prepare the site carefully. Start by identifying the exact entry and exit points for the tunnel. This ensures the machine follows the correct path. Next, excavate small pits, known as jacking and receiving shafts, at these points. These shafts provide access for the machine and the pipes.

You also need to assess the soil conditions. Conducting a geotechnical survey helps you understand the type of soil and any potential obstacles. Once you complete the survey, install the jacking frame in the entry shaft. Secure it firmly to ensure stability during operation. Finally, connect the machine to the power and hydraulic systems, and verify that all components are functioning properly.

Excavation and Pipe Installation

The excavation process begins once the machine is in place. The cutting head at the front of the micro pipe jacking machine breaks through the soil. As it moves forward, hydraulic jacks push the pipes into position. The machine removes the excavated material through a spoil removal system, keeping the workspace clean.

You install each pipe section one at a time. After pushing one section forward, you add the next section and repeat the process. This method ensures a seamless connection between the pipes. The machine’s design allows it to handle various soil types, making it reliable in different environments.

Alignment and Quality Control

Maintaining proper alignment is crucial during the operation. Use the machine’s guidance system to monitor its position. Many machines include laser guidance, which helps you achieve precise results. Regularly check the alignment to ensure the tunnel follows the planned route.

Quality control doesn’t stop at alignment. Inspect the installed pipes for any gaps or misalignments. Addressing these issues immediately prevents future problems. You should also monitor the machine’s performance throughout the process. This ensures consistent results and reduces the risk of delays.

Benefits of Micro Pipe Jacking Machines

Precision and Accuracy

A micro pipe jacking machine offers unmatched precision during tunnel installation. Its advanced guidance systems, such as laser technology, help you maintain exact alignment throughout the process. This ensures that the pipes follow the planned route without deviation. You can trust this machine to deliver consistent results, even in complex underground environments. The precise operation reduces the risk of errors, saving you from costly corrections later.

Efficiency and Time Savings

When you use a micro pipe jacking machine, you significantly reduce the time required for tunnel installation. The machine combines excavation and pipe installation into one seamless process. This eliminates the need for separate steps, speeding up the project timeline. Its hydraulic jacks and spoil removal systems work efficiently, allowing you to complete tasks faster. You also save time by avoiding the extensive surface restoration required with open-cut methods.

Minimal Surface Disruption

One of the biggest advantages of a micro pipe jacking machine is its ability to minimize surface disruption. You don’t need to dig large trenches, which means roads, sidewalks, and landscapes remain intact. This is especially beneficial in urban areas where surface damage can cause major inconveniences. By preserving the surface, you reduce environmental impact and avoid disrupting daily activities in the area.

Micro pipe jacking machines revolutionize underground construction. You’ve seen how they streamline tunnel installation with precision, efficiency, and minimal surface disruption. Their applications in utilities, energy, and telecommunications make them indispensable for modern infrastructure. By adopting this technology, you contribute to sustainable and minimally invasive construction, ensuring long-term benefits for urban and rural development.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY