အရည်အသွေးမြင့် ပိုက်ဂျက်ကင်းစက် ကတ်တာ

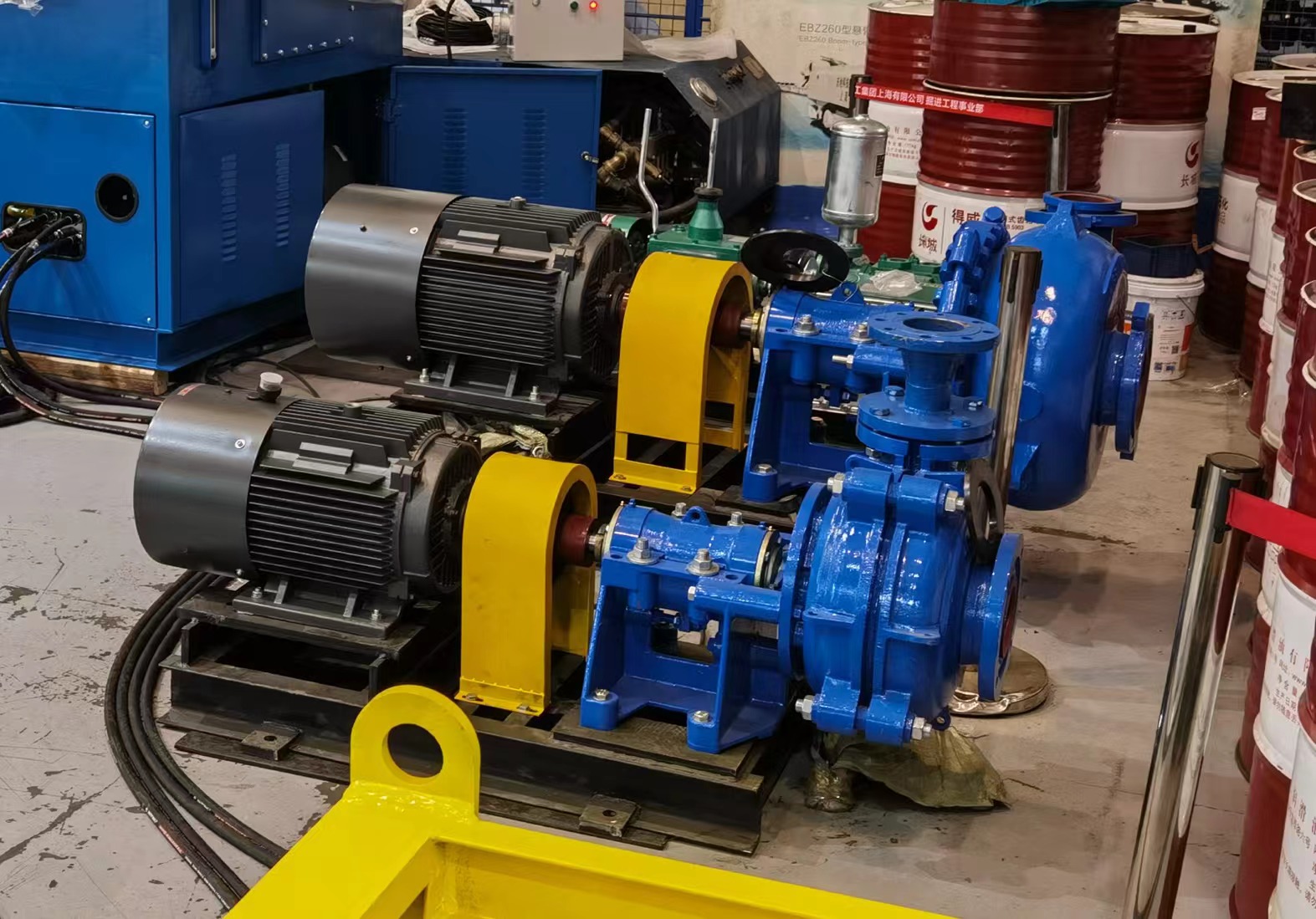

အရည်အသွေးမြင့် ပိုက်ဂျက်ကင်းစက်က သင်္ဘောမလိုအပ်သော နည်းပညာအတွက် ဒီဇိုင်းထုတ်ထားသော တီထွင်ဆန်းသစ်သော ကိရိယာဖြစ်ပြီး မြေအောက်ပိုက်လိုင်းများကို တိကျမှုနှင့် ထိရောက်မှုဖြင့် ထည့်သွင်းရန် အထောက်အကူပြုသည်။ ၎င်း၏ အဓိကလုပ်ဆောင်ချက်များတွင် မြေကြီးနှင့် ကျောက်ကို ဖြတ်တောက်၍ ပိုက်လိုင်းအတွက် လမ်းကြောင်းတစ်ခု ဖန်တီးခြင်းနှင့် အချိန်တစ်ခုတည်းတွင် ပိုက်ပိုင်းများကို ထည့်သွင်းခြင်းတို့ ပါဝင်သည်။ ၎င်းကိရိယာ၏ နည်းပညာဆိုင်ရာ အင်္ဂါရပ်များတွင် အထူကြီး သံထုတ်လုပ်မှု၊ အစားထိုးနိုင်သော ဖြတ်တောက်သွားများနှင့် ၎င်း၏ လှုပ်ရှားမှုများကို စွမ်းအားပေးသော အဆင့်မြင့် ဟိုက်ဒရောလစ်စနစ် ပါဝင်သည်။ ၎င်းစက်၏ အမျိုးမျိုးသော အသုံးပြုမှုများသည် မြို့ပြ ပြုပြင်ထိန်းသိမ်းရေး စီမံကိန်းများမှ စ၍ ကြီးမားသော အခြေခံအဆောက်အအုံ ဖွံ့ဖြိုးတိုးတက်မှုများအထိ အသုံးပြုနိုင်စေပြီး မျက်နှာပြင်ကို အနည်းဆုံး ထိခိုက်မှုနှင့် သဘာဝပတ်ဝန်းကျင်ကို အနည်းဆုံး သက်ရောက်မှုရှိစေသည်။

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY