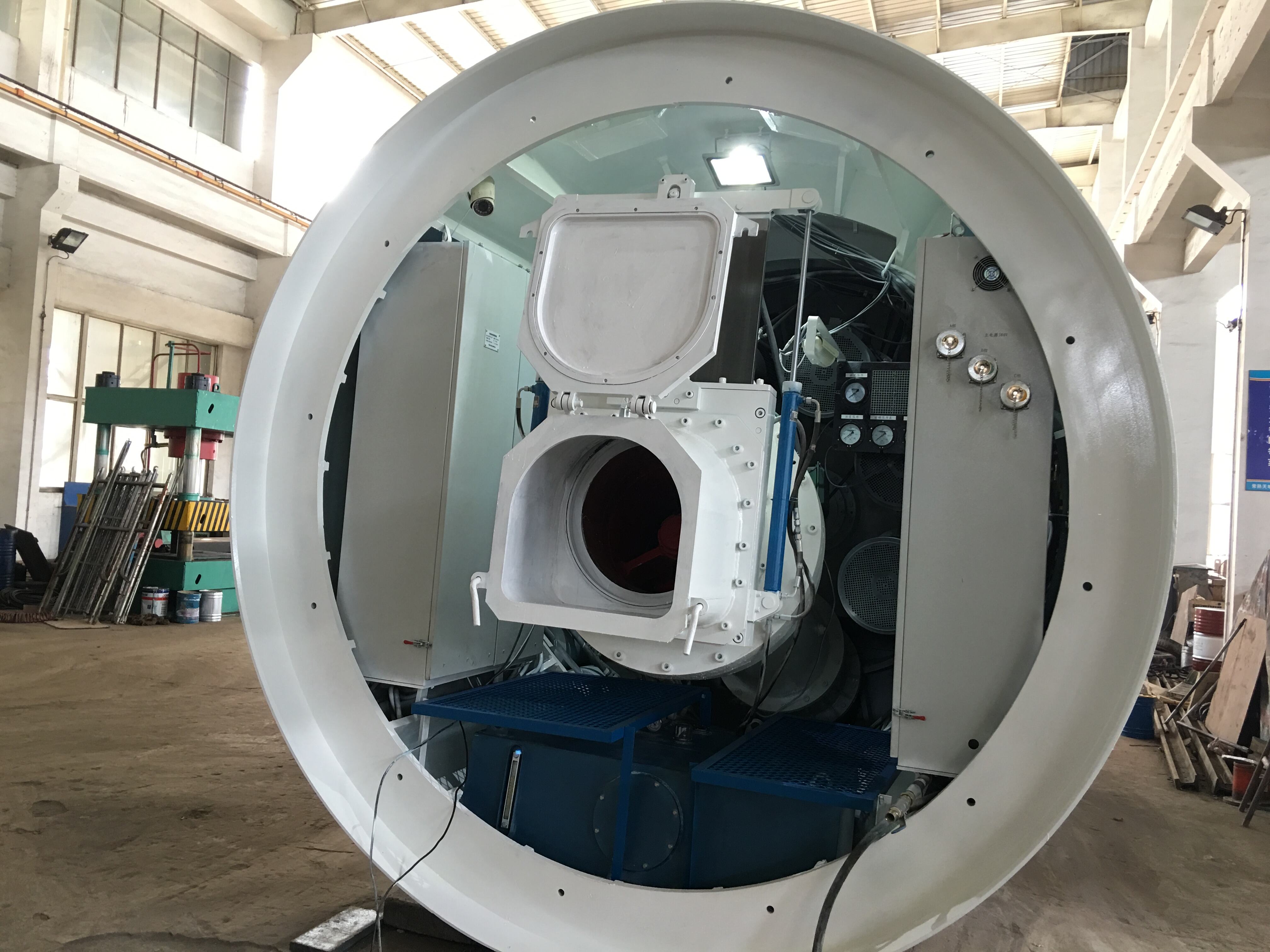

Як працює система балансування шламом у машинах для прокладання труб?

Вступ Що стосується прокладання труб, це техніка безтраншейного будівництва трубопроводів для прокладання доріг або водних шляхів без значних порушень. Процес, що включає простий метод використання машини для прокладання труб...

Дивитися більше

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY