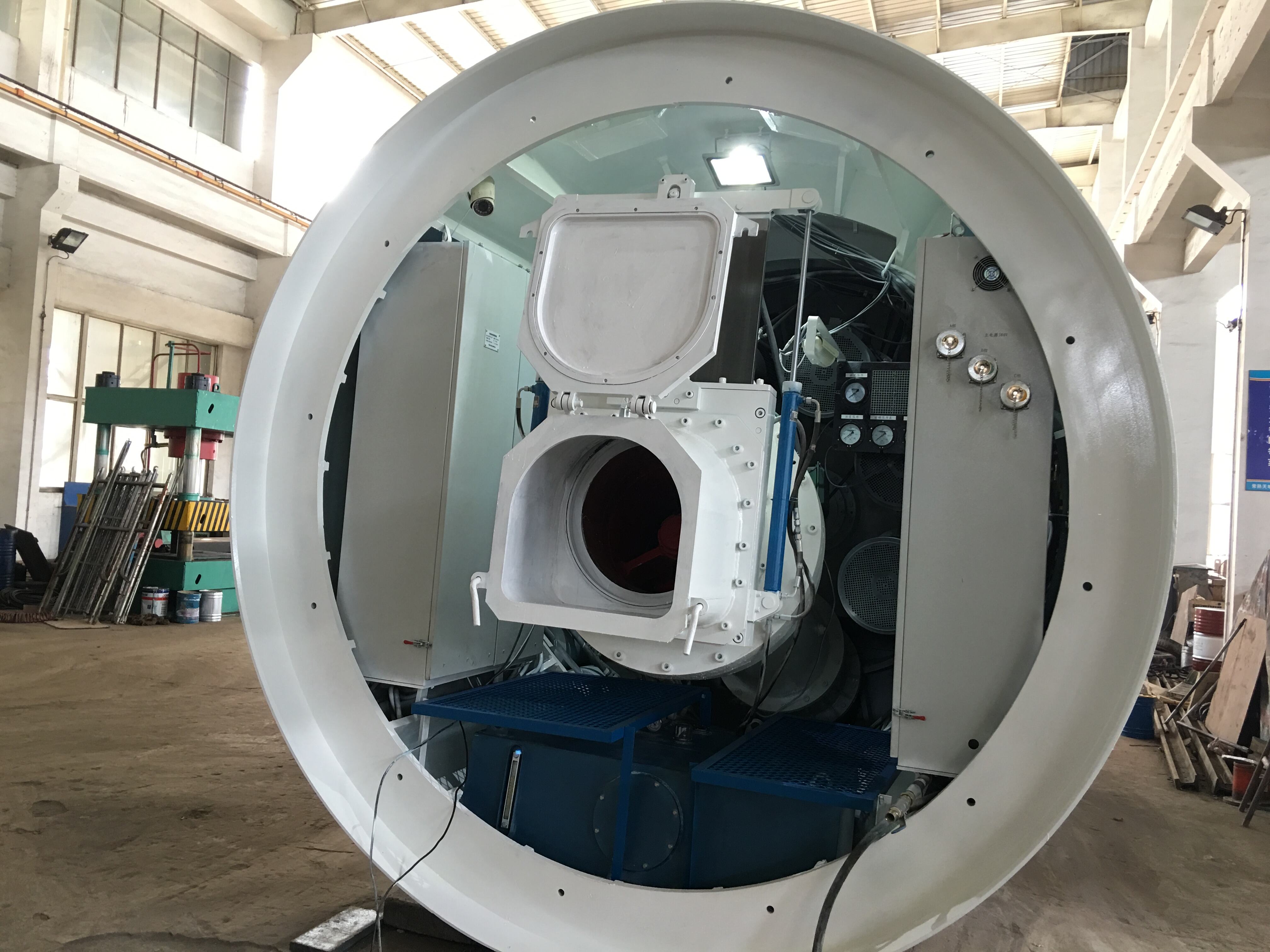

дорожня тунельна бурильна машина

Машина для буріння тунелів є дивом сучасної інженерії, розробленою для ефективного викопування тунелів через різні типи ґрунту та породи. Її основні функції включають буріння, різання та видалення ґрунту, одночасно встановлюючи підтримуючі структури тунелів, такі як бетонні сегменти. Технологічні особливості цих машин включають сучасні комп'ютерні системи управління, кілька різальних головок для різних умов ґрунту та автоматизовані системи для видалення викопаного матеріалу. Ці машини використовуються в різних сферах, від будівництва метрополітенів і дорожніх тунелів до створення комунікаційних тунелів для транспортування води, газу та електрики. Їхня міцна конструкція та точність роблять їх незамінними в розвитку підземної інфраструктури.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY