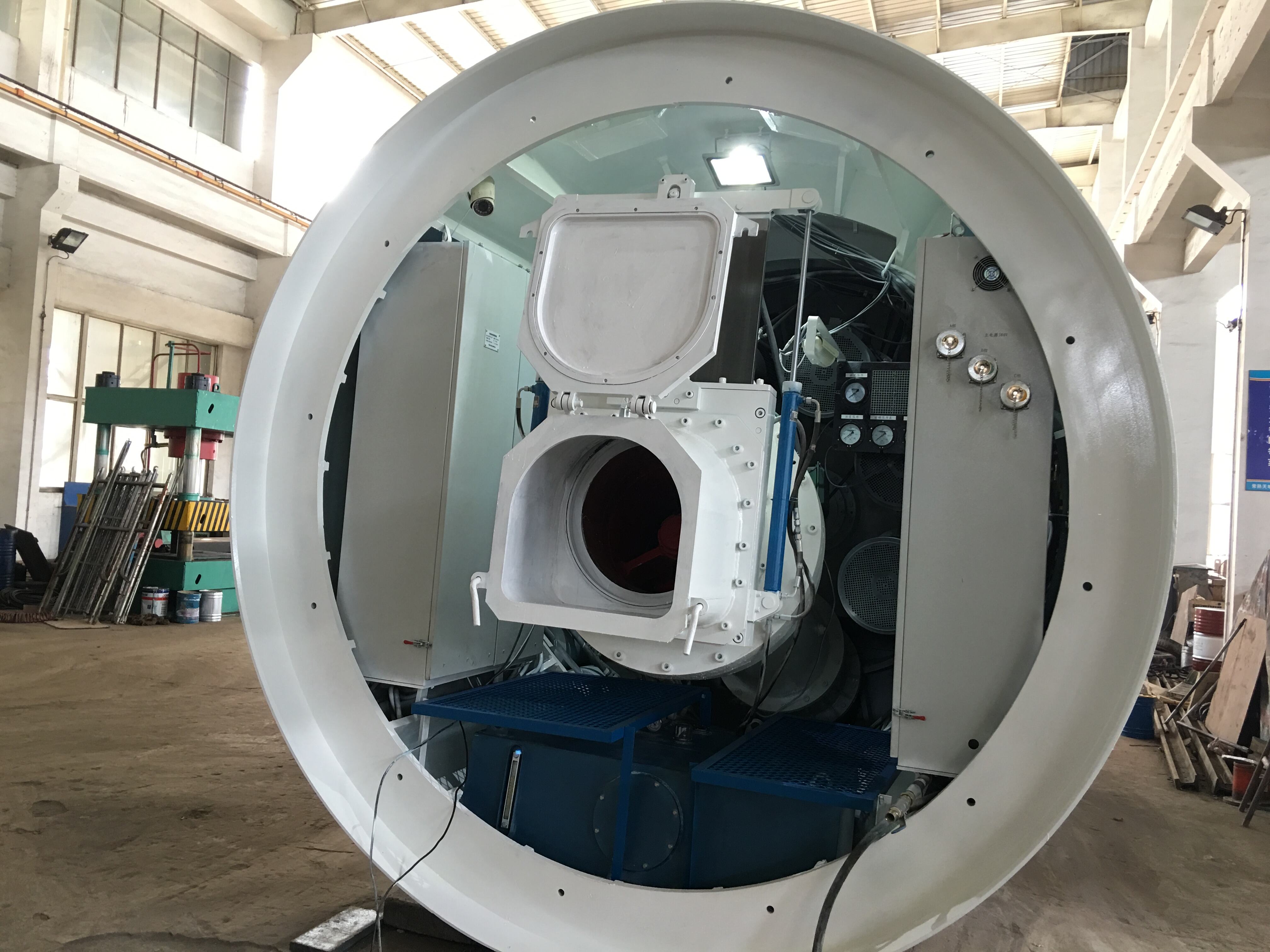

massiewe tonnelboormasjien

Die massiewe tonnelboormasjien is 'n staat-van-die-kuns stuk toerusting wat ontwerp is om doeltreffend tonnels deur verskillende terreine te grawe. Sy hooffunksies sluit in boor, sny, en die verwydering van grond en rots soos dit vorder, wat 'n tonnel skep wat van 'n paar meter tot verskeie kilometers in deursnee kan wissel. Tegnologiese kenmerke soos 'n draaiende snykop, gevorderde sensors vir presisie, en gekomputeriseerde beheerstelsels vir navigasie en werking, maak dit 'n wonder van moderne ingenieurswese. Die masjien word in 'n verskeidenheid toepassings gebruik, insluitend vervoernetwerke, watervervoer, en infrastruktuurontwikkeling, wat beduidend bydra tot die vooruitgang van stedelike en landelike projekte.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY