tunnel drilling machine

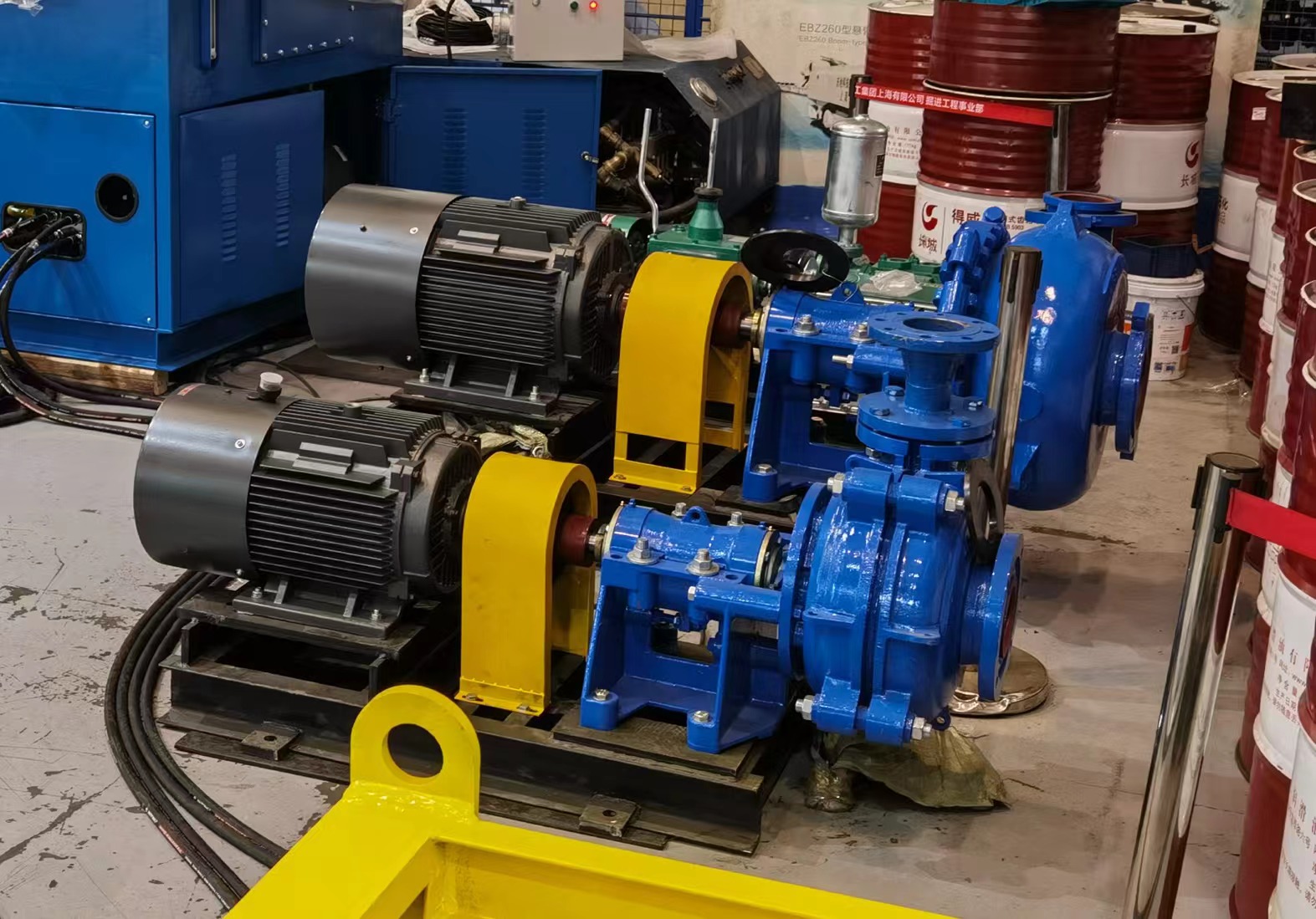

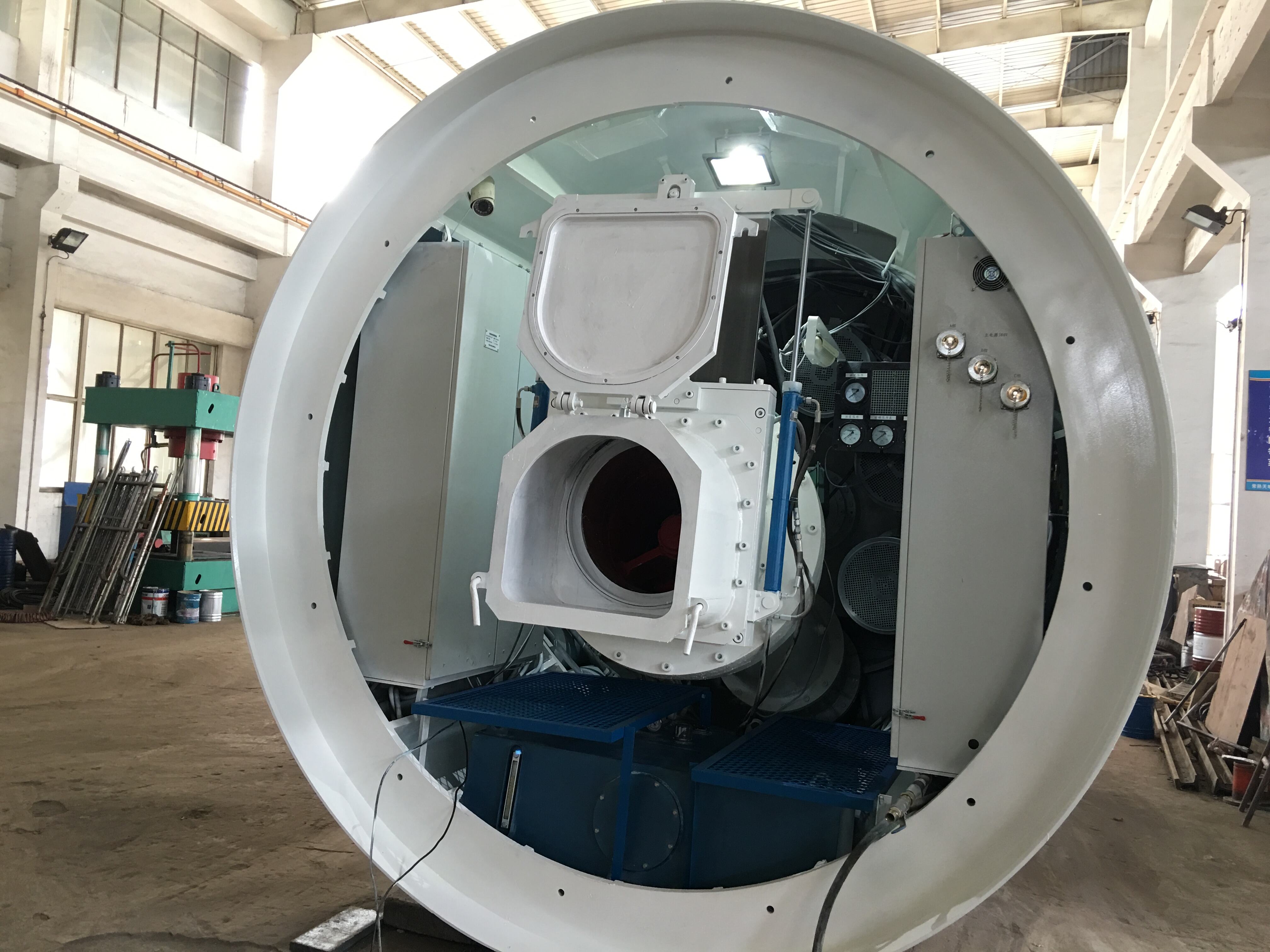

The tunnel drilling machine represents the pinnacle of engineering innovation designed for underground excavation. Its primary function is to bore through soil and rock to create tunnels with precision and efficiency. Equipped with state-of-the-art technological features such as a robust drill head, automated control systems, and advanced hydraulics, this machine ensures optimal performance even in the most challenging environments. The tunnel drilling machine is versatile in its applications, from mining and construction to infrastructure development, making it an indispensable tool in various industries. With the capacity to handle different types of geological formations, it streamlines the process of tunneling, enhancing safety and reducing project timelines significantly.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY