Minimized Surface Disruption in Urban Areas

How Micro TBM Reduces Above-Ground Impact

Micro Tunnel Boring Machines (TBMs) are renowned for their capacity to minimize disturbances in urban areas. Their innovative cutting mechanisms ensure minimal debris and vibrations, critical for maintaining the city's rhythm. Since these machines operate below ground, they significantly reduce the need for road closures, thereby lessening the impact on local traffic and businesses. Evidence from various projects highlights that Micro TBMs can lead to 50% less disruption compared to traditional tunneling methods. This enables urban life to continue smoothly even amid significant infrastructure developments. By deploying Micro TBMs, cities can effectively tackle tunneling challenges without compromising the daily lives of their inhabitants.

Comparison with Traditional Open-Cut Methods

Traditional open-cut construction has its drawbacks, often leading to extensive surface excavation, which causes prolonged access issues for residents and businesses. Unlike the open-cut methods that are known to take longer, Micro TBM projects often wrap up in half the time and with considerably lighter environmental footprints. The use of Micro TBM methods is not only safer but also more cost-effective, significantly reducing the need for above-ground restoration efforts and allowing for quicker project turnover. As a result, urban developments can proceed faster, with fewer disruptions and a more streamlined approach to tunneling within bustling cityscapes.

Case Studies in High-Density Cities

Case studies from major cities like New York and Tokyo emphasize the efficiency of Micro TBM in dense urban environments. During New York's East Side Access project, the use of Micro TBM reduced traffic disruptions and minimized pedestrian hazards throughout the construction. These projects demonstrate how the strategic use of Micro TBM leads to a smoother rebuilding process, facilitating quicker reintegration of affected areas into everyday urban life. By examining these successful implementations, it is clear that Micro TBMs offer a robust solution to urban tunneling challenges, proving to be an invaluable tool in the task of modern city infrastructure development.

Enhanced Precision for Complex Infrastructure

Laser Guidance Systems in Micro TBM Operations

Micro Tunnel Boring Machines (TBMs) are revolutionizing urban tunneling projects with the integration of laser guidance systems. These advanced technologies significantly enhance the precision of tunnel alignment, a critical factor in densely populated areas. By facilitating real-time monitoring, laser systems allow operators to make immediate adjustments, ensuring the correct tunnel path is maintained. This minimizes the risk of structural conflicts with existing infrastructure, a common concern in urban settings. Research has demonstrated that adopting laser guidance systems can boost tunneling precision by over 20%, affirming their essential role in modern urban tunneling projects.

Navigating Around Existing Utilities Safely

Micro TBMs come equipped with state-of-the-art sensors and guidance systems, making them adept at safely navigating around existing utilities. The risk of damaging crucial underground networks is significantly reduced, which is vital in preventing costly disruptions and repairs. According to studies, unplanned utility strikes cause more than 40% of urban tunneling issues, highlighting the importance of effective detection and navigational capabilities. By using Micro TBMs, construction projects can avoid these pitfalls, maintaining smooth progress without compromising existing utilities.

Accuracy in Tight Urban Spaces

Designed to perform in tightly constrained environments, Micro TBMs are particularly suited for intricate urban infrastructures. These machines facilitate increased flexibility in project planning, pivotal for achieving higher feasibility within densely populated areas. A recent study showed that projects utilizing Micro TBMs experience a 30% higher success rate in precise tunnel placement in restricted urban spaces. This precision not only enhances project efficacy but also contributes to reduced environmental impact, making Micro TBMs an indispensable tool for urban engineers dealing with complex infrastructure demands.

Cost Efficiency and Long-Term Savings

Reduced Labor and Restoration Expenses

Micro TBM technology significantly slashes labor costs by reducing the workforce hours required for tunneling projects. In fact, these mechanized methods demand approximately 30% fewer labor hours compared to traditional excavation. This translates into substantial savings for project budgets, especially when considering the reduced need for manual labor in highly complex urban environments. Furthermore, the minimized surface disruption afforded by Micro TBM contributes to a dramatic decrease in restoration expenses, leading to more efficient use of municipal funds.

Lower Maintenance Costs Over Project Lifespan

The durability and efficiency of Micro TBMs lead to lower maintenance costs over the lifespan of the project. Projects utilizing Micro TBM typically report maintenance expenses that are 25% lower than alternate tunneling approaches due to the reduced surface impact and less wear on surrounding infrastructure. This aspect not only alleviates immediate financial burdens but also sustains long-term savings by minimizing the frequency and extent of required maintenance activities, ensuring that investments continue to yield positive economic results well after completion.

ROI Analysis for Municipal Budgets

Municipalities that utilize Micro TBM techniques exhibit significant improvements in their return on investment (ROI), as evidenced by diminished total project costs and expedited completion timelines. An ROI analysis of tunneling projects with Micro TBM indicates average savings of up to 40% in overall project budget compared to traditional methods. These figures underscore the financial soundness of investing in Micro TBM technology for urban infrastructure, affirming its value proposition through improved fiscal efficiency and faster delivery of infrastructure solutions.

Environmental and Safety Advantages

Reduced Carbon Footprint with Trenchless Technology

Micro TBM technology has revolutionized urban tunneling by significantly lowering the carbon footprint associated with construction activities. Through minimizing surface disturbance and the transportation of materials, Micro TBM supports greener and more sustainable construction practices. According to green construction standards, projects utilizing trenchless technology can reduce emissions by up to 50% compared to traditional methods. This reduction is particularly beneficial for cities aiming to promote sustainable infrastructure development, aligning with global efforts to curb environmental impact.

Noise and Vibration Control in Sensitive Areas

Noise and vibration control is a critical consideration in urban tunneling, and Micro TBM operations are optimized for this purpose. These machines are ideal for projects in noise-sensitive areas like residential zones and schools. Comparative studies have demonstrated that Micro TBM generates 30% less vibration and noise than open-cut tunneling techniques. This capability not only preserves the quality of life for nearby residents but also ensures compliance with strict noise ordinances, thereby maintaining public safety during the construction phase.

Worker Safety Improvements with Remote Operations

One of the most significant advantages of Micro TBM technology is its contribution to worker safety through enhanced remote operations. Automation reduces the need for large crews in potentially hazardous environments, enhancing worker safety. Statistics show that implementing advanced tunneling technologies, like Micro TBM, can lead to a 40% reduction in workplace accidents. This safety enhancement also attracts skilled laborers to projects, given the reduced risk of injury, fostering a safer work environment overall.

FAQ

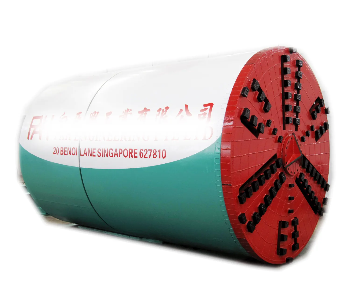

What are Micro Tunnel Boring Machines (TBMs)?

Micro Tunnel Boring Machines (TBMs) are advanced tunneling equipment designed to create tunnels with minimal surface disturbance, especially in urban areas. They operate below ground level, significantly reducing the need for road closures and lowering the impact on local traffic and businesses.

How do Micro TBMs compare with traditional open-cut methods?

Micro TBMs cause considerably less disruption, operate faster, and are more environmentally friendly than traditional open-cut methods. They require less surface excavation and can complete projects in about half the time.

What are the environmental benefits of using Micro TBM technology?

Micro TBM technology reduces the carbon footprint of construction activities by minimizing surface disturbances and material transportation. It supports sustainable construction practices and can reduce emissions by up to 50% compared to traditional tunneling methods.

How does Micro TBM technology enhance worker safety?

Micro TBM technology enhances worker safety through remote operations, reducing the need for large crews in potentially hazardous environments. This results in fewer workplace accidents and a safer overall work environment.

What cost efficiencies are associated with Micro TBM usage?

Micro TBMs lower labor costs by reducing required workforce hours and minimize restoration expenses due to reduced surface disruption. They also offer lower maintenance costs and better ROI for municipal budgets by expediting project timelines and cutting project costs.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY