What is a Micro TBM in Modern Tunnel Construction?

Definition and Core Components

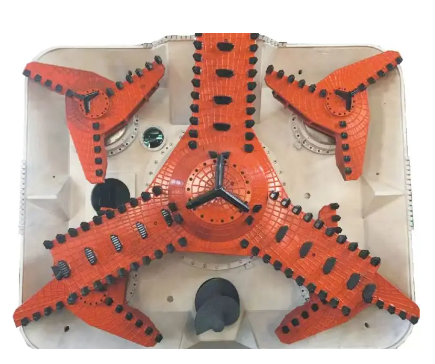

Micro TBM, or Micro Tunnel Boring Machine, is a compact and specialized machine designed to excavate tunnels with a diameter typically less than 1.5 meters. These machines play a crucial role in urban settings where space constraints do not allow for larger tunneling equipment. The core components of a Micro TBM include a cutterhead that rotates to break soil and rock, a thrust system that propels the machine forward, and a segmental lining that stabilizes the tunnel walls during the excavation process. Additionally, these machines integrate either a slurry system or dry excavation technology. This integration is vital as it helps manage excavation waste and water ingress, ensuring efficient excavation even in challenging conditions.

How Micro TBMs Differ from Conventional TBMs

Micro TBMs differ significantly from conventional TBMs in terms of size and operational capabilities. While traditional TBMs are used for large-diameter tunnels, Micro TBMs are designed for tighter spaces and more complex urban environments. They can navigate difficult geological conditions that would challenge larger machines. This includes the unique capability of operating in modes that allow for flexibility and precision in varied strata. Furthermore, Micro TBMs enhance project efficiency by reducing ground disturbance. They also enable simultaneous utility installation, streamlining construction processes and minimizing disruptions, especially in densely populated urban areas.

Key Applications in Urban Infrastructure

Micro TBMs are pivotal in transforming urban infrastructure. Their key applications include the installation of water and sewer systems, utility tunnels, and transportation networks like subways. They are also instrumental in environmental projects such as stormwater management systems. Globally, successful projects utilizing Micro TBMs underscore their effectiveness; for instance, several cities have implemented them for essential utility upgrades without significantly impacting normal urban life. A sterling example is the deployment of Micro TBMs in Tokyo's sewer renovation project, combining precision with minimal disruption. These machines are undeniably shaping the future of urban tunneling and are essential to managing modern urban infrastructure challenges.

Advantages of Micro TBM Technology

Precision Engineering for Minimal Surface Disruption

Micro TBMs utilize precision engineering to limit surface disruption, a crucial factor in bustling urban areas. These machines are specifically designed to tunnel beneath existing structures with minimal impact, effectively addressing urban excavation concerns. They enable tunneling under roads and buildings without causing visible disturbances. For instance, minimizing surface disruption translates directly into reduced traffic interruptions and less environmental disturbance, which is essential in busy city environments. This precision engineering makes Micro TBM a preferred choice in densely populated areas.

Cost-Effectiveness in Small-Diameter Projects

Micro TBMs offer significant cost benefits for small-diameter projects due to their lower operational expenses compared to larger TBMs. Traditional tunneling methods often entail higher costs and longer project durations, whereas Micro TBMs provide a more economical alternative. Comparative statistics indicate reduced project costs and timelines when employing Micro TBM technology. Furthermore, the need for extensive surface restoration is significantly lessened with Micro TBMs, saving both time and financial resources, thereby making them a cost-effective solution for targeted tunneling tasks.

Enhanced Safety Features for Workers

The design of Micro TBMs includes enhanced safety features that prioritize automated systems, thereby minimizing the need for direct human intervention near excavation sites. This automation leads to a notably reduced risk of accidents compared to traditional methods that typically involve larger work crews and more manual processes. For example, the use of Micro TBMs has been linked to improvements in workplace safety statistics, underscoring their role in creating a safer working environment. These advancements exemplify the commitment to worker safety in modern tunnel construction.

Micro TBM vs Traditional Tunneling Methods

Comparison with Drill-and-Blast Techniques

Micro TBM technology stands out against traditional drill-and-blast methods primarily through its mechanization and efficiency, offering significant advancements for tunneling projects. Unlike conventional techniques, Micro TBMs minimize the noise, vibration, and dust associated with drill-and-blast techniques, contributing substantially to improving air quality and preserving urban environments. The automation inherent in Micro TBMs leads to a streamlined process with less dependence on manual labor, reducing the environmental footprint. Industry data consistently shows that the environmental impact of Micro TBM tunneling is lower due to these advancements, highlighting the shift towards cleaner and quieter construction solutions in populated areas.

Environmental Impact Reduction Analysis

Micro TBM technology significantly reduces the carbon footprint tied to tunneling projects by using precision engineering to minimize surface disruption and require fewer materials. This technology is particularly adept at mitigating adverse impacts on ecosystems and urban settings, aligning with sustainability goals. Studies have quantified these benefits by examining projects that utilized Micro TBMs, illustrating discernible improvements in environmental standards compared to traditional methods. This analysis confirms Micro TBMs' potential for transformative effects on the industry, demonstrating their eco-friendly advantages over traditional tunneling practices.

Time Efficiency in Complex Urban Projects

Deploying Micro TBMs in urban settings provides remarkable time efficiency compared to traditional tunneling techniques. Their ability to swiftly navigate complex underground terrains results in reduced project timelines and expedited completion. For instance, notable urban projects have experienced significant time savings, with Micro TBMs accelerating the construction process by seamlessly integrating into intricate city layouts. Case studies substantiate these claims, showcasing superior scheduling outcomes with Micro TBMs due to their precise automation coupled with efficient operational capabilities. This timely advancement enhances productivity, illustrating Micro TBMs as a preferred choice for urban infrastructure development.

Innovations Driving Micro TBM Efficiency

Automated Guidance Systems

Automated guidance systems are revolutionizing the operational efficiency of Micro TBMs. By utilizing precision sensors and advanced software, these systems enhance navigation within tunnels, ensuring precise alignment and minimizing human error. This technology not only improves the accuracy of tunnel construction but also significantly enhances the speed and efficiency of projects. Notably, projects that have adopted automated guidance systems report a reduction in deviation from planned routes and improved alignment accuracy, leading to smoother project outcomes and lowered costs.

Advanced Cutterhead Designs for Varied Geology

The innovation in cutterhead design has vastly improved the performance of Micro TBMs across a variety of geological conditions. Modern cutterheads are equipped with adaptive technology that allows them to adjust to different soil and rock types seamlessly. This adaptability is crucial for maintaining smooth and efficient operations when tunneling through varied geology. For instance, in a recent project in urban settings, advanced cutterhead designs enabled uninterrupted progress and minimized downtime, demonstrating their effectiveness in managing geological challenges and maintaining project timelines.

Real-time Monitoring through IoT Integration

The integration of IoT technology has significantly impacted real-time monitoring of Micro TBM operations. By collecting and analyzing data during tunneling, these systems provide actionable insights to enhance performance and preempt issues. IoT-enabled sensors can track numerous parameters such as pressure, temperature, and vibration, offering a comprehensive view of the tunneling environment. Successful IoT implementations, such as those seen in major city infrastructure projects, have led to marked improvements in efficiency and safety, as teams can address potential hazards proactively and adjust strategies accordingly.

Future Trends in Micro TBM Development

AI-powered Predictive Maintenance

AI-powered predictive maintenance holds great potential in enhancing the reliability of Micro TBM operations while minimizing downtime. By analyzing operational data, AI systems can predict when maintenance is necessary, preventing sudden breakdowns and extending equipment life. Already, some tunneling projects witness this revolutionary application of artificial intelligence. For instance, certain large-scale projects use machine learning algorithms to process data from sensors, thereby forecasting maintenance needs accurately. As AI systems continually evolve, they promise unparalleled operational efficiency and reliability, transforming the landscape of tunnel construction while reducing costs through proactive equipment management.

Hybrid Energy Systems for Sustainability

The integration of hybrid energy systems into Micro TBM technology is gaining traction as a sustainable tunneling solution. These systems, often combining electric and biodiesel sources, significantly cut down environmental impact by reducing carbon emissions and energy consumption. Research consistently supports the environmental advantages of these systems. Studies have demonstrated their capacity to decrease greenhouse gas emissions during tunneling projects, highlighting their role in promoting sustainable construction practices. As the emphasis on sustainable infrastructure deepens, hybrid energy systems within Micro TBMs will likely continue to develop, contributing to eco-friendly tunnel construction.

Nano-TBM Concepts for Ultra-Precise Microtunneling

Nano-TBM concepts are emerging as a transformative trend, providing prospects for ultra-precise microtunneling applications. These cutting-edge concepts are poised to revolutionize industries requiring high precision, such as electronics and telecommunications infrastructure. Although still largely in the theoretical phase, initial designs suggest these Nano-TBMs will offer unprecedented control and accuracy in confined spaces. Initial projects exploring these designs aim to demonstrate their feasibility and practical application. The promise of Nano-TBMs lies in their potential to overcome the limitations of traditional tunneling methods, ushering in an era of precision that meets the rigorous demands of modern infrastructure development.

In embracing these trends, the future of Micro TBM development becomes a cornerstone of sustainable and technologically advanced tunneling solutions, paving the way for record-breaking and more efficient construction projects.

FAQ

What is a Micro TBM?

A Micro TBM, or Micro Tunnel Boring Machine, is a compact machine used in tunneling projects with diameters typically less than 1.5 meters. They are ideal for urban environments with limited space.

How does a Micro TBM differ from a conventional TBM?

Unlike conventional TBMs used for large tunnels, Micro TBMs are designed for smaller spaces and complex urban settings. They allow for minimal ground disturbance and precise tunneling in tight conditions.

What are the applications of Micro TBMs?

Micro TBMs are commonly used for installing water and sewer systems, utility and transport tunnels, and environmental projects like stormwater management.

What benefits do Micro TBMs offer?

Micro TBMs offer advantages such as precision engineering that minimizes surface disruption, cost-effectiveness for small projects, and enhanced safety features for workers.

Why are Micro TBMs preferable in urban infrastructure?

They are preferable because they reduce noise, vibration, and dust, have a lower environmental footprint, and improve time efficiency, making them suitable for complex urban settings.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY