Quels sont les facteurs clés à prendre en considération lors du choix d'une machine de prise de tuyaux à l'équilibre en lisier pour un projet?

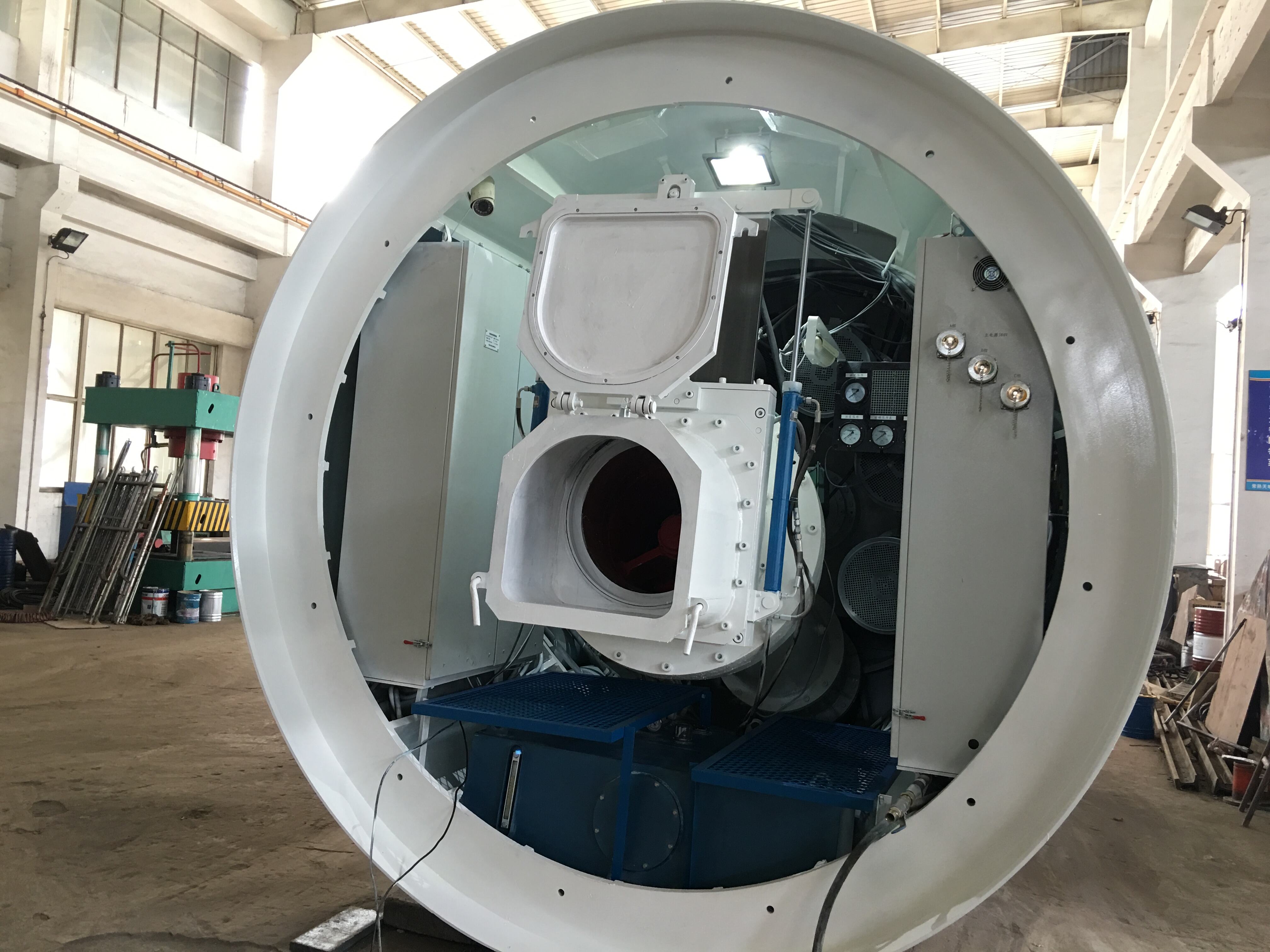

Le raccordement des tuyaux fait également référence à une méthode de construction sans tranchées dans laquelle le tuyau est installé sous terre avec l'aide d'une machine de raccordement. Les rotateurs de la machine de remontage de tuyaux à équilibre en lisier peuvent particulièrement traiter des troubles de la saleté compliqués, et sont largement utilisés pour progr...

VOIR PLUS

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY