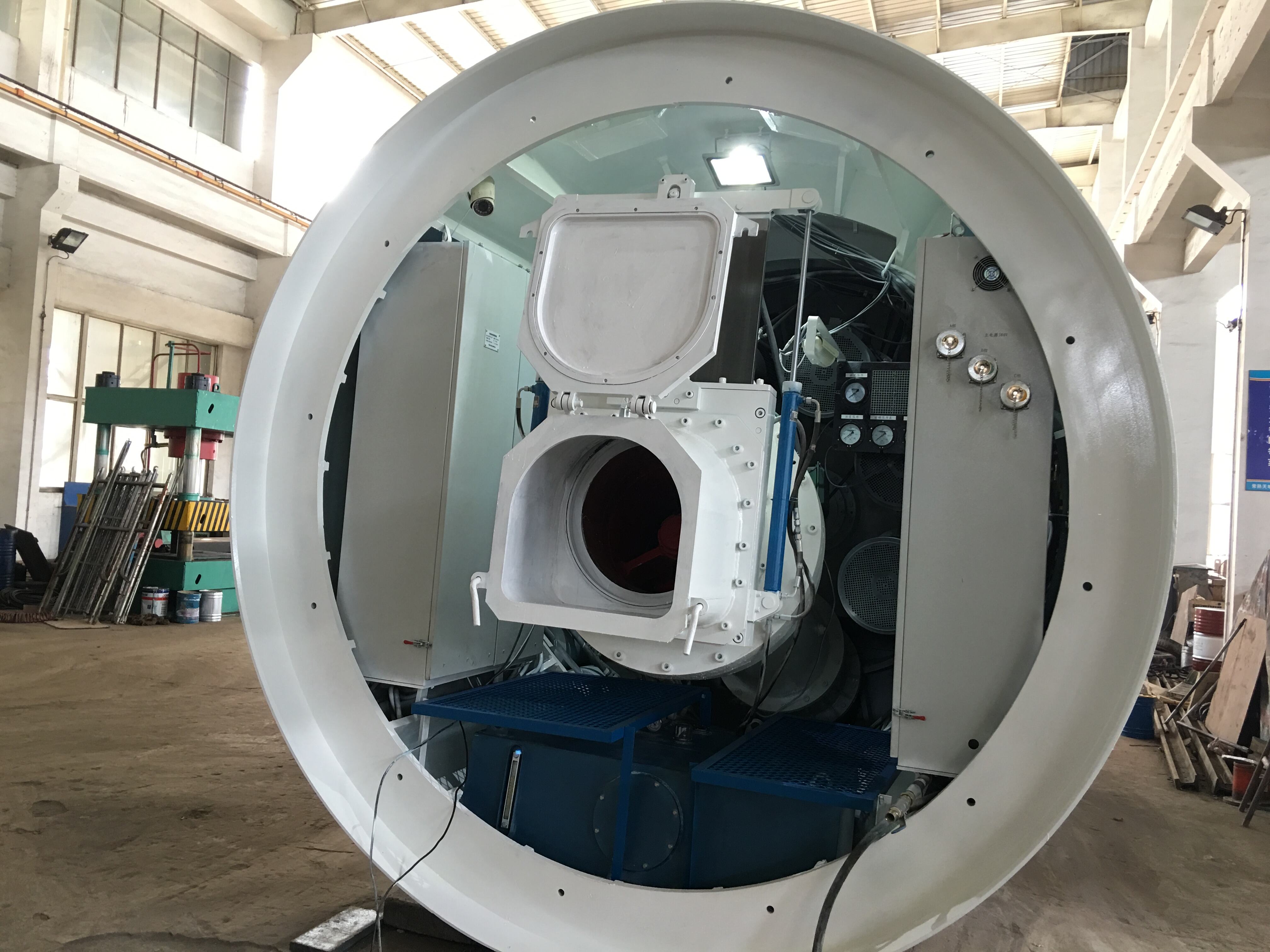

mašina za kanalizacijski tunel

Stroj za tuneliranje kanala, također poznat kao stroj za bušenje tunela (TBM), izvanredan je inženjerski uređaj dizajniran za učinkovito iskopavanje tunela kroz razne terene. Njegove glavne funkcije uključuju bušenje, rezanje i uklanjanje tla i stijena dok napreduje, stvarajući stabilno okruženje tunela. Tehnološke značajke stroja za tuneliranje kanala uključuju rotirajuću reznu glavu, sustav transporta za uklanjanje otpada i napredne senzore za navigaciju i kontrolu. Ovi strojevi se koriste u raznim primjenama, od izgradnje podzemnih željeznica i autocesta do postavljanja cjevovoda i stvaranja podzemnih prolaza. Preciznost i brzina TBM-ova revolucionirali su industriju tuneliranja, čineći projekte izvedivijima i manje ometajućima za površinu.

EN

EN

AR

AR BG

BG HR

HR CS

CS FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO RO

RO RU

RU ES

ES TL

TL ID

ID LT

LT SK

SK SL

SL UK

UK VI

VI ET

ET TH

TH TR

TR FA

FA AF

AF MS

MS HY

HY AZ

AZ KA

KA BN

BN LO

LO LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY